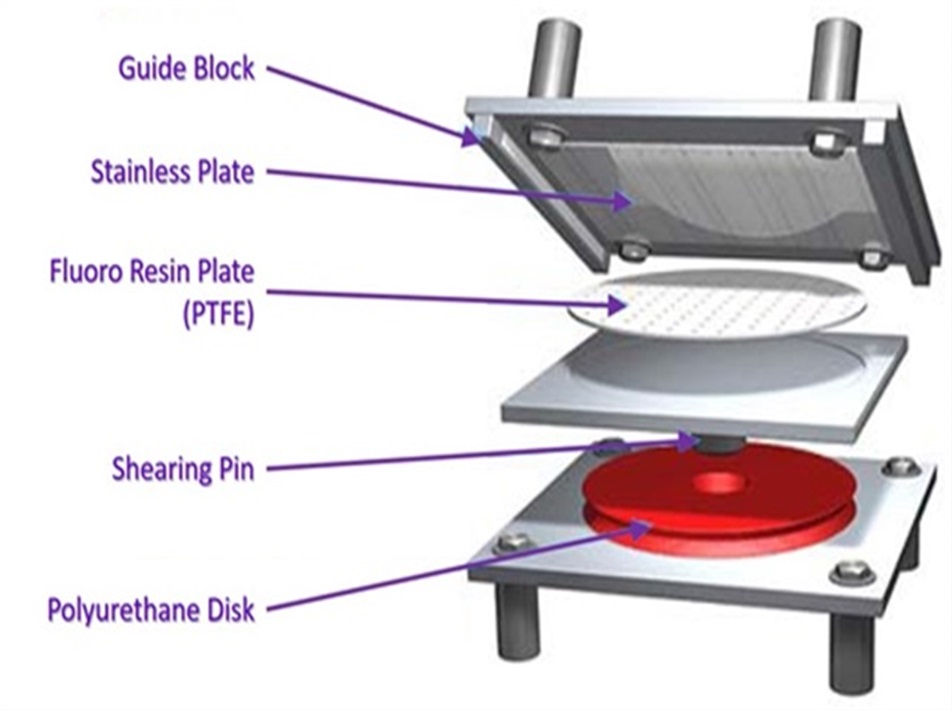

Disc Bearing

Gantek Disc Bearings provide a lower profile compared to traditional pot bearings, making them ideal for applications where space is limited. Despite this, they offer the same load capacity and movement, ensuring reliable performance.

A key advantage of disc bearings is their design, which eliminates the need for rubber seals to retain the elastomer. This improves their durability, offering a longer service life and reducing maintenance costs.

Additionally, disc bearings are cost-effective and easier to fabricate, offering superior rotational performance. Their simpler design provides a more efficient solution for uplift bearing applications, making them easier to integrate into both new projects and retrofits.

In short, Disc bearings deliver a combination of performance, durability, and cost-efficiency, making them a versatile choice for various applications.

The physical property requirements for disc bearing elastomers are shown below:

Table: Physical Property Requirements for Disc Bearing Elastomer

| Physical Properties | ASTM Test Method | Requirement (Min) |

|---|---|---|

| Hardness, Shore D | D-2240 | 62±2 |

| Tensile strength | D-412 | 34.5 MPa |

| Ultimate elongation | D-412 | 220% |

| 100% modulus | D-412 | 13.8 MPa |

| 200% modulus, Aged physical after 70 hours | D-412 | 25.5 MPa |

| @100 degree Celsius | D-573 | - |

| Hardness change, max | - | ±2 |

| Tensile strength change, max | - | +15, -0 |

| Elongation change, max | - | +20, -0 |