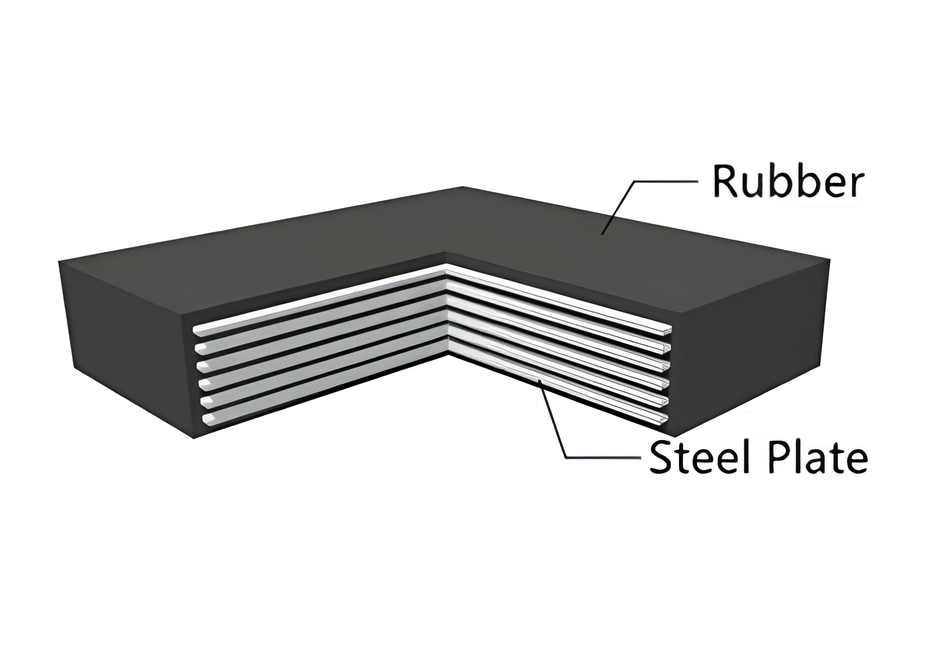

Elastomeric Bearing Pad

Gantek Elastomeric Laminated Bearing Pads, featuring simple reinforcement, consist of multiple layers of elastomer material separated by reinforcing steel plates. These layers are sulfurized and molded together to form a durable, cohesive structure. These bearing pads can be manufactured in rectangular or circular shapes to meet specific engineering requirements.

These bearings are typically used in applications such as bridges with spans of less than 30 meters and where small displacements are expected. They are designed to provide reliable load transfer while accommodating vertical, shear, and rotational movements. By ensuring flexibility in the system, elastomeric bearings help mitigate the stresses that occur due to movement and expansion, ensuring the longevity and performance of the structure.

Our elastomeric bearings are manufactured in compliance with rigorous standards, including those set by ASTM (American Society for Testing and Materials) and AASHTO (American Association of State Highway and Transportation Officials), ensuring that they meet the highest quality and performance requirements for various engineering projects.

| Physical Propeties | ASTM Test Method | Requirement | ||

|---|---|---|---|---|

| Hardness, Shore A | D-2240 | 50±5 | 60±5 | 70±5 |

| Tensile Strength | D-412 | > 15.5 MPa | > 15.5 MPa | > 15.5 MPa |

| Ultimate Elogation | D-412 | 450% | 400% | 300% |

| Peel Strength of Rubber bonded to Steel Plate (N/mm) | D-429, B | > 7.0 | > 7.0 | > 7.0 |

| Low Temperature Brittleness (℃) | D-746 | < -40 | < -40 | < -40 |

| Permanent Deformation at constant Compression (%) | D-395 | < 25 | < 25 | < 25 |

| Oven Aging, 168 hrs, @70℃ Hardness change, max. | D-573 | 10 | 10 | 10 |

| Tensile strength change, max. | D-573 | -25% | -25% | -25% |

| Elongation change, max. | D-573 | -25% | -25% | -25% |

| Ozone Resistance, 48 hrs, @40℃ | D-1149 | No Crack | No Crack | No Crack |